Introduction to Led Curable Ink

In the ever-evolving world of printing technology, led curable ink has emerged as a transformative force. This innovative ink type cures instantly upon exposure to LED light, offering print professionals enhanced precision and vibrancy in their work. Whether you’re in the textile, packaging, or graphic arts industry, understanding the benefits and applications of led curable ink is crucial to staying competitive. This article will guide you through the advantages, applications, and setup processes that make led curable ink a top choice among modern printing solutions.

Advantages of Using Led Curable Ink

One of the primary advantages of led curable ink lies in its efficiency. Unlike traditional inks that require extended drying times, led curable ink dries instantly when exposed to LED light, significantly boosting production speed. Moreover, this ink method is notably eco-friendly, emitting minimal VOCs compared to solvent-based inks. Additionally, its low energy consumption correlates with reduced operational costs, which is a benefit that many printing businesses are keen to exploit. Thus, adopting led curable ink not only enhances workflow but also aligns with sustainable practices that are increasingly valued in today’s market.

Setup Process for Led Curable Ink

Setting up a printing system to effectively use led curable ink involves a series of steps. Firstly, ensure that your printing machine is compatible with LED technology, as this is pivotal for achieving optimal results. Once confirmed, the ink must be properly loaded into the printer, following the manufacturer’s guidelines carefully. It is also essential to calibrate the LED light system to the prescribed wavelengths to guarantee that the ink cures effectively without any defects. Many users find it beneficial to conduct small test prints to fine-tune settings before committing to larger jobs. This careful setup enables print shops to maximise both quality and efficiency in their productions.

Insights from an Industry Perspective

Fostering a clear understanding of the market dynamics surrounding led curable ink is key for any industry professional. Colleagues utilizing this ink have reported significant improvements in print durability, particularly in challenging environments. For instance, a notable case involved a local signmaking company that switched to led curable ink for outdoor signage. The results were remarkable; the signs retained their vibrancy far longer than those printed with conventional inks. Furthermore, led curable inks are less prone to fading when exposed to UV light, addressing a common concern for many businesses focused on long-lasting imagery.

Exploring Led UV Ink Manufacturer Options

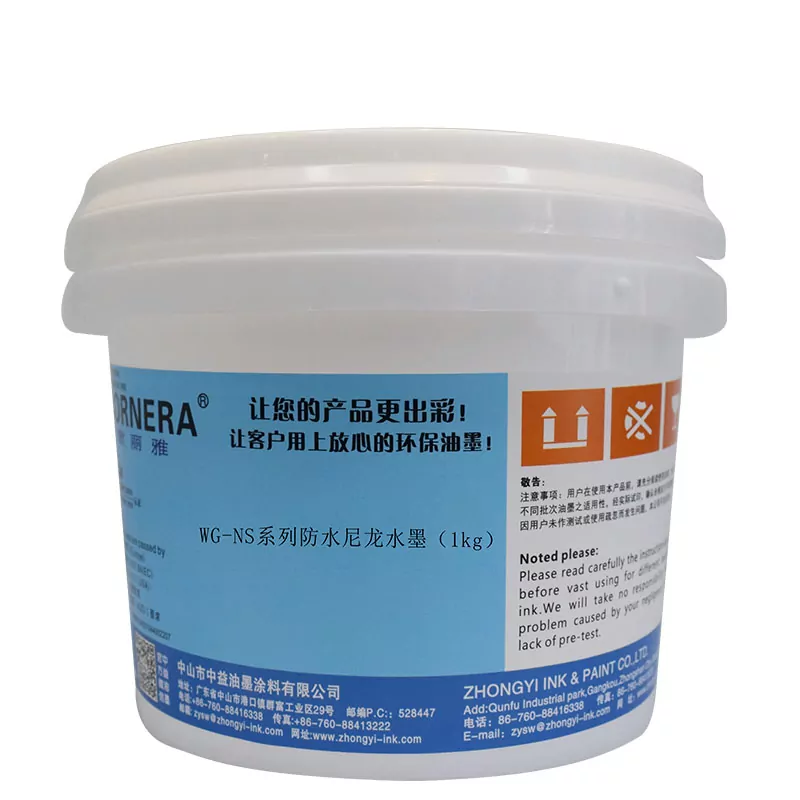

When sourcing led curable inks, it’s imperative to engage with a credible led uv ink manufacturer. This recommendation stems from the necessity to ensure quality, consistency, and reliability in ink supply. Manufacturers with a solid reputation, such as Zhongyiink, dedicate themselves to ensuring that their products undergo rigorous testing to maintain the highest standards, ensuring their clients receive the best possible materials for their printing needs. Selecting a noted manufacturer not only reflects good business practice but also significantly impacts the overall printed result.

Understanding Led UV Offset Inks

In the realm of offset printing, led uv offset inks have become increasingly prominent for their streamlined performance and vibrant finish. These inks offer instant drying capabilities that are particularly advantageous for high-volume print jobs where efficiency and quality are paramount. Offset processes benefit from led uv inks as they can adhere to a variety of substrates, from paper to plastics, thereby broadening the potential applications for print businesses. By integrating led uv offset inks into their workflow, print operations can not only elevate their output quality but also reduce their environmental footprint.

Conclusion and Brand Recommendation

In conclusion, the shift towards led curable ink in the printing industry represents a significant enhancement in both performance and sustainability. With advantages such as efficiency and lower energy consumption, it is vital for businesses to embrace this innovative technology. For sourcing high-quality materials, manufacturers like Zhongyiink provide unparalleled supply advantages that can help print operations thrive in a competitive marketplace. Their commitment to excellence makes them a trusted partner for any business looking to implement led curable ink solutions.